13

Sep

Sep

RADEX®-N COMPOSITE

Product characteristics

|

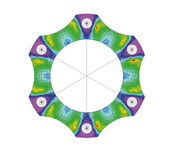

FEM-optimized laminae form

| The steel laminae packings from stainless spring steel were developed on the basis of FEM calculations. Under consideration of the necessary possibilities of displacements of the coupling the optimal form regarding torque transmission and torsional rigidity was aimed for. The fitted form of the steel laminae at the outside diameter is the result of this optimization calculation. |

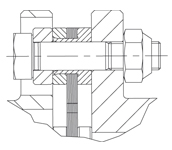

Laminae packings with sdowel screws

The „heart“ of the steel laminae coupling are the laminae packings and their connection to the hubs or spacers.

High-strength, special dowel screw that are alternately screwed with hubs and spacer enable a combination of frictional engagement and positive locking. Thus a high power density with simultaneous easy displacement and low restoring forces is guaranteed.

Due to the special constructive design of the RADEX®-N components the laminae packings are „artificially“ prestressed. Hereby the torsional rigidity of approx. 30 % is enabled and at the same time the known problem regarding the axial vibrations of the spacer is avoided.