7

Sep

Sep

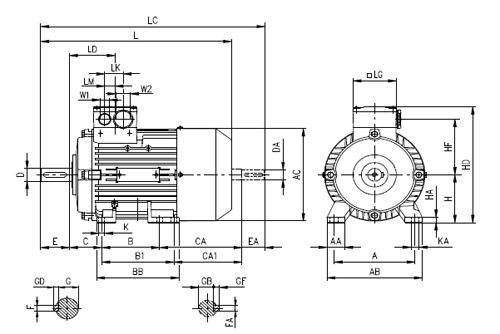

INDUCTION MOTORS 7AA SERIES FRAME 56-90

Basic Motor Design Features

The 7AA series motors in frame sizes 56-90 are three-phase squirrel-cage induction electric motors of IP 55 protection (CD rings are used to seal the shaft/endshield gaps, Oil seals must be specified in your Order if protection against oil penetration is required) in accordance with IEC 34-5 (EN 60034-5, CSN 350001), with IC 411 surface self cooling according to IEC 34-6 (EN 60034-6, CSN EN 60034-6).

The output and specification of the motors comply with IEC 34-1 (EN 60034-1, CSN 35 0000, Part 1). Motor frames are of die-cast aluminium. Foot mounted motors have feet cast-on the die cast frame. The terminal box is produced from die-cast aluminium as well. Terminal box is located on top as standard, frame sizes 80 and 90 can be supplied as foot mounted motors with terminal box located either on the right or on the left (when viewing the drive end shaft). Terminal box cable entries enabling the cable entry to rotate by 90° and are closed with plugs. surface self cooling according to IEC 34-6 (EN 60034-6, CSN EN 60034-6).

Endshields are of grey cast iron.

Fans are plastic, fan cowls are made of steel sheet.

Motor winding is of copper wire of Insulation Class "F" with temperature rise of Class "B" according to IEC 85 (CSN 33 0250).

The rotor cage is made of die-cast aluminium. The rotor lamination stack is pressed onto the shaft, dynamically balanced with half-key and fitted with ball bearings. The drive end shaft is provided with a tapped hole according to DIN 332 (see table 1).