Sep

BOWEX®JUNER

|

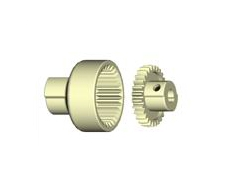

BoWex® Curved-tooth gear couplings® are flexible shaft connections for a positive torque transmission and specifically suitable to compensate for axial, radial and angular shaft misalignment.

According to the well-known effect of curved-tooth gear couplings any edge pressure in the spline in case of angular and radial displacements is avoided so that BoWex couplings are almost free from wear.

The material polyamide allows for maintenance-free continuous operation with very low friction on the teeth.

Due to the double cardanic operation of BoWex® couplings restoring forces may be neglected in case of angular and radial displacements and periodic fluctuations in angular velocity do not arise.

BoWex® couplings can be assembled both vertically or horizontally with no need for any special assembly tools.